by Charles Q. Choi: Just as solar cells generate electricity from sunlight, thermophotovoltaic cells do so from infrared light…

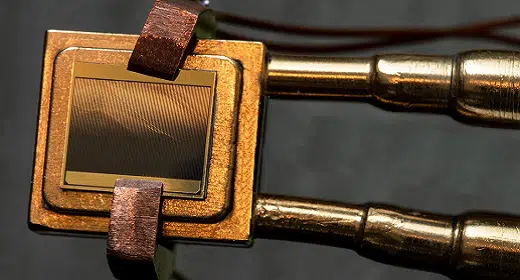

Now, in a new study, scientists have revealed thermophotovoltaic cells with a record-high conversion efficiency of more than 40 percent, better than the average turbines used to generate power in the United States. These findings could help enable grid-scale thermal batteries for renewable energy, which could help make power grids carbon-free, the researchers say.

The way in which most power plants generate electricity is with turbines. In a turbine, a fluid such as steam is driven by, say, the heat from combustion, nuclear energy, or solar heat to spin the rotor shaft of a generator, which converts the kinetic energy of the fluid to electricity.

The average efficiency of turbine-based power generation in the United States is less than 35 percent, says study lead author Alina LaPotin, a mechanical engineer at MIT. However, turbine costs and performance have reached full maturity, so there are limited prospects for their future improvement.

“A turbine-based power production system’s cost is usually on the order of US $1 per watt. However, for thermophotovoltaics, there is potential to reduce it to the order of $0.10 per watt.”

—Asegun Henry, MIT

In contrast, thermophotovoltaics are very early in their progress, and so may have numerous prospects to improve their efficiency and costs, LaPotin notes. For instance, whereas turbines depend on moving parts that can melt when they get hot enough, thermophotovoltaics are solid-state devices that can operate at higher temperatures, which can unlock a variety of benefits.

Scientists first created thermophotovoltaics with efficiencies of 29 percent roughly 40 years ago. However, despite predictions that their efficiencies would exceed 50 percent, for decades their efficiencies reached only as high as 32 percent.

In the new study, the researchers experimented with thermophotovoltaic materials optimized for emitter temperatures of 1,900 to 2,400 °C and emitting infrared photons with energies between 1 and 1.4 electron volts. (One electron volt is the work performed on a single electron as it is accelerated through 1 volt of potential difference—equal to 0.16 quintillionths of a joule, or an attojoule.) These single-photon energies are higher than those explored by previous thermophotovoltaic research, with the aim of avoiding efficiency-reducing voltage losses seen with thermophotovoltaics that exploit lower-energy infrared photons. The present study also targets higher temperatures than those of prior thermophotovoltaics. The rule of thumb in this case, LaPotin says, is that the greater the temperature, the higher the power density of the devices and the lower their cost in relation to the power they generate.

The scientists also boosted the efficiency of their devices with highly reflective back surfaces that bounced lower-energy infrared photons back at the emitters. These reflected photons go on to heat the emitters, allowing them to emit the higher-energy infrared light that’s more useful for the new thermophotovoltaics.

“It’s a big deal when someone actually demonstrates high efficiency, because talk is cheap,” says Asegun Henry, MIT professor of mechanical engineering. “I think it signals that thermophotovoltaics are worth a deeper look—are worth more investment and more development, because so many technologies look promising on paper, with modeling results that show high efficiencies are possible, but then for whatever reason, they never materialize.”

The 1.2–1.4 electron-volt device has the advantage of operating at a higher voltage and thus at a lower current density for a given emitter temperature, which can reduce energy losses due to electrical resistance, LaPotin says. In contrast, the 1–1.2 electron-volt device has the advantage of operating at a higher power density at a given emitter temperature, she notes.

The efficiency of these devices can increase to more than 50 percent with better reflectors, the researchers say. A reflector in a study from another group in 2020 attained reflectivity of more than 98 percent. Combining such a reflector with the new thermophotovoltaics could lead to efficiencies of more than 56 percent at 2,250 °C, or more than 51 percent on average over a range of 1,900 to 2,400 °C, the scientists say.

“I think the most important implication is that thermal batteries can move forward to commercialization, even with the current cell performance we demonstrated here.”

—Asegun Henry, MIT

These new findings suggest that thermophotovoltaics could help generate power at lower costs than turbines. “A turbine-based power production system’s cost is usually on the order of US $1 per watt,” Henry says. “However, for thermophotovoltaics, there is potential to reduce it to the order of $0.10 per watt.”

A key potential application for these new thermophotovoltaics is a grid-scale thermal battery. Such a system would absorb surplus electricity from renewable sources such as the sun and store that energy in heavily thermally insulated banks of a material such as silicon or graphite. When that energy is needed, such as on overcast days, thermophotovoltaic cells would convert this heat into electricity and dispatch the energy on demand to a power grid.

“Thermal batteries are great applications for thermophotovoltaics because they need to be done at bigger scales to make the system efficiency equal to the device efficiency,” Henry says.

Although such thermal energy-grid storage was initially conceived with molten silicon as the thermal battery material, graphite would prove even cheaper at roughly $0.50 per kilogram, resulting in a projected capital cost of less than $10 per kilowatt-hour, low enough to help make renewable energy cost-competitive with fossil fuels, the scientists note.

“I think the most important implication is that thermal batteries can move forward to commercialization, even with the current cell performance we demonstrated here,” Henry says.

The devices in the new study are about a square centimeter in size. For a grid-scale thermal-battery system, Henry envisions thermophotovoltaic cells roughly 1,000 square meters in size operating in climate-controlled warehouses to draw power from huge banks of stored solar energy. He notes that infrastructure exists for making large-scale photovoltaic cells that could also be adapted to manufacture thermophotovoltaics.

The scientists detailed their findings online 13 April in the journal Nature.