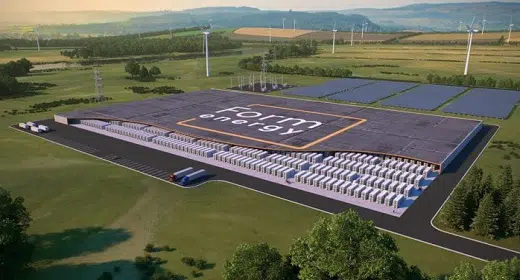

by Amit Malewar: Form Energy, Inc., a technology company, announced the battery chemistry of its first commercial product and a $200 million Series D financing round led by ArcelorMittal’s XCarb innovation fund…

Solar and wind resources are the lowest marginal cost sources of electricity in most of the world. Solar, wind, and other forms of green energy produce power as and when it’s available. And as the world starts to transition away from cheap, responsive, and heavily polluting energy sources like coal, the electric grid now faces a challenge: how to manage the multi-day variability of renewable energy, even in periods of multi-day weather events, without sacrificing energy reliability or affordability.

In 2017, Tesla built and installed the world’s largest lithium-ion battery at Hornsdale in South Australia, which was a huge success. But there are inherent issues with lithium batteries; they are expensive, better suited to quick turnaround than long-term storage.

However, Form Energy is focused on developing low-cost energy storage technology to enable a reliable, secure, and fully renewable electric grid year-round. The Massachusetts-based startup recently unveiled a new rechargeable iron-air battery capable of delivering electricity for 100 hours at system costs competitive with conventional power plants and at less than 1/10th the cost of lithium-ion.

The active components of the iron-air battery system are some of the safest, cheapest, and most abundant materials on the planet – low-cost iron, water, and air. This front-of-the-meter battery can be used continuously over a multi-day period and will enable a reliable, secure, and fully renewable electric grid year-round.

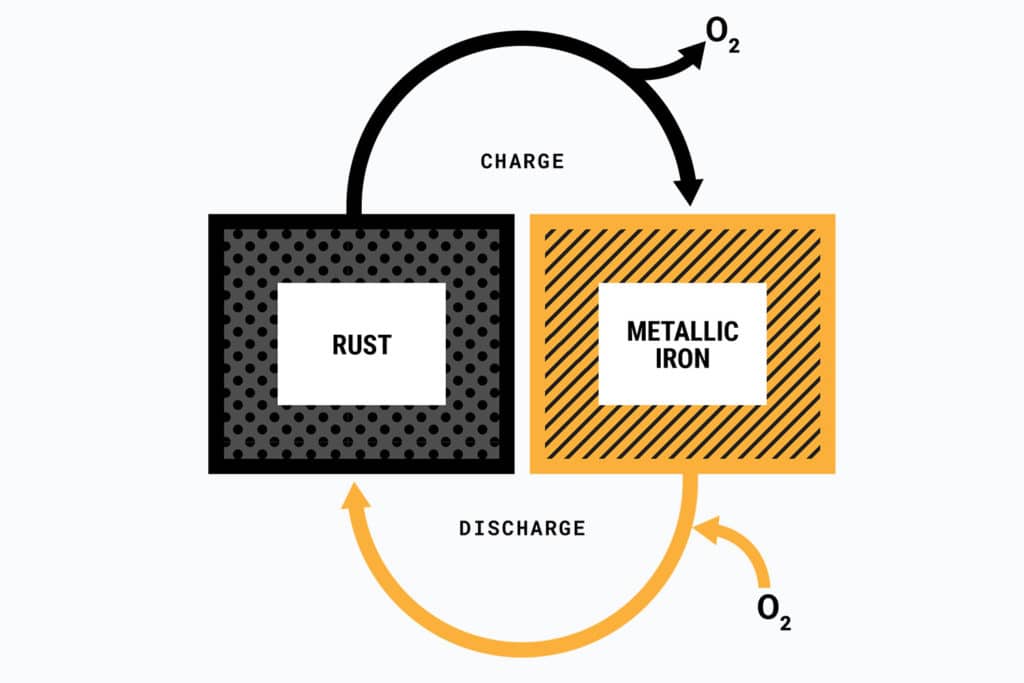

The basic principle of operation of an iron-air battery is reversible rusting. While discharging, the battery breathes in oxygen from the air and converts iron metal to rust and energy. And the charging cycle turns rust into metallic iron, storing energy and releasing oxygen.

Each battery module – about the size of a washing machine – is filled with a water-based, non-flammable electrolyte. Inside of the liquid electrolyte is stacks of between 10 and 20 meter-scale cells, which include iron electrodes and air electrodes, the parts of the battery that enable the electrochemical reactions to store and discharge electricity. These battery modules are grouped together in modular megawatt-scale power blocks, delivering up to 3MW of continuous power per acre.

In addition, when the system comes at the end of its service life, the materials are highly recyclable.

Steel giant ArcelorMittal has invested $25 million in Form Energy and will potentially provide iron for its long-life batteries.

According to the company, this new battery technology can make renewable energy available when and where it’s needed, even during multiple days of extreme weather or grid outages.

Source: Inceptive Mine