by Chanan Bos: Tesla’s Battery Day was not just full of surprises…

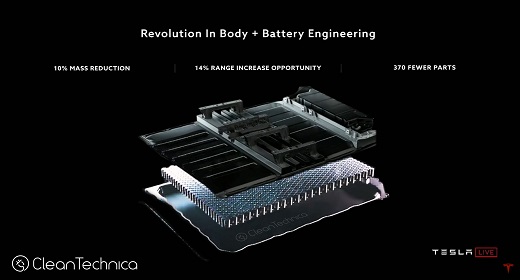

When you read between the slides, Tesla made a lot of product announcements, many of which are still awaiting their discovery. The one this article is about is Tesla’s new battery pack.

What most people didn’t realize is that Tesla is abandoning its famous battery skateboard design. For those who didn’t know, until now, Tesla’s vehicles were composed of the body and a flat battery “skateboard” on the bottom that, as Tesla would say, are married together in the factory. We even witnessed the ceremony in person. Originally, the skateboard design was developed because it provided a low center of gravity and strong safety benefits, as well as the ability to quickly swap battery packs instead of just Supercharging if Tesla went down that road.

Tesla Model S Skateboard Design

As you know, that last part didn’t end up happening. Now Tesla has gone back to the drawing board to make something better. However, it wasn’t just out of Tesla’s habit of successfully reinventing the wheel. The company has gone back to the drawing board because its cream-of-the-crop 4680 battery cells required it. You see, in the past, battery cells weren’t dense enough, so Tesla needed all the room it could get in the floor. If Tesla was to still do that now, vehicles would have incredible range, but Tesla wouldn’t be able to make a lot of them.

Tesla had to solve a few issues. First, the company needed to find a way to simplify the battery pack and eliminate modules. Next, without the skateboard, Tesla needed a new way to shore up the structural integrity of the vehicle. What they ended up doing is turning luggage into structure the same way that an airplane has made fuel tank–shaped wings rather than wings that have tanks inside.

In some ways, it’s the same trick Tesla has applied to its starship design, where the body itself is part of the fuel tank. This is also not the first time Elon has applied lessons learned in one company to the products of another. In this case, the solution was a glue (material substance pun intended) that not only acted as both glue and a flame retardant as it did in previous models, but also as a material to strengthen the pack. Sandwich that between two steel sheets and you make the battery pack rock solid and shear resistant. It no longer requires outside support. Unlike CATL, which has started putting cells in the pack directly and eliminating modules, this is practically a cell-to-vehicle solution, since the battery pack is no longer just an enclosure, it’s part of the structure of the vehicle.

Tesla’s new pack kills more than 2 birds with one stone, though, because there are a couple of other things this new architecture enables. Now, without the battery pack extending to the front and the back of the vehicle, it has even more effective crumple zones as well as more room. This leads us to yet another benefit. Sure, that extra room could be left empty and used for more luggage. Or, perhaps, rather than a bigger frunk, the vehicle could get a large HEPA filter enabling bioweapon defense mode. Even with the HEPA filter, there would likely still be a larger frunk than today. It is hard to overestimate just how much extra room there will be, and part of that will likely even extend to a larger cabin as well.

The end result? Tesla was beating around the bush a bit regarding how much more effective the structural integrity was. During Battery Day, Elon Musk touted it as a good solution for solving the structural integrity issues of cabriolet vehicles, but did not directly compare it to internal combustion engine (ICE) vehicles or his own existing vehicles. Until a tweet this week, that is, in which Elon — coincidentally, replying to my tweet — clarified that it is more rigid and a major breakthrough.

Funny enough, it appears that he did not actually answer my question. Or did he? You see, all of this very much connects to injection mold casting as well as the patent for a unibody design we saw more than a year ago.

You see, with the new battery pack, Tesla can go on to the next phase with its unibody injection molding ambitions. In the end, this will only work if the floor is not a part of the unibody, since the completed mold is ejected upwards and then lifted off of the machine. They don’t need to make a floor for structural integrity, because the battery pack takes on that role. Tesla will likely proceed with this in stages. So, is it a coincidence that, to the question of whether Tesla will cast the middle part of the vehicle as a single piece, Elon answers about the the breakthrough battery that would make it possible? Well, if you need more convincing, below are some more “coincidences,” starting with a specific excerpt from that patent:

“Such casting machines may reduce a number of casting machines or actual castings required to cast a complete or substantially complete vehicle frame (e.g., to less than six, less than five, less than four, less than three, less than two, or one casting machine(s)).”

For the Model Y, or maybe for the $25,000 Model Placeholder in Giga Berlin, it’s possible that Tesla will use a casting machine like it does for the rear body assembly in Fremont, one for the front counterpart, and then the next step, the middle section of the body, will be added as was highlighted in one of the images in the patent.

Most interestingly, the way the company currently stamps and welds this part of the body together, at some stage it looks exactly like what you see in the image above. Two side panels of exactly that shape are then connected by two roof struts, a front part that separates the hood section from the cabin, and the rear part. Thanks to the structural battery pack, the body can be casted and pushed up and out of the machine.

Now, returning to my tweet, that is exactly what I was asking about. In that tweet, I did accidentally write “stamp” rather than “cast,” but that Elon replied about the structural battery pack in response to a question regarding unibody casting makes me think Elon was confirming that the structural battery pack makes it possible. The patents clearly state that this casting technique could take place in parts, and not just as one single unibody. It’s quite likely that one is a stepping stone to the other. It is also rather likely that unibody stamping will allow Tesla to make significantly cheaper vehicles, like the $25,000 Model Placeholder or the eventual ultra-cheap robotaxi discussed in my previous article in this chain of Battery Day articles.

This article was already written for the most part before Elon Musk replied to my tweet. At the time, I wrote that the actual unibody design won’t be implemented until Tesla figures out full self driving and can avoid crashes, since a unibody is a lot more often going to be unfixable, and thus expensive to insure. However, Elon also responded to a comment on that tweet of his in which something new was revealed.

This means that repairability is not the limiting factor of unibody casting. It is still, however, not something Tesla will implement immediately. There is the possibility that Tesla might introduce this with its low-cost vehicle or low-cost robotaxi, and that would explain why both Giga Berlin and Giga Shanghai can introduce their own, different looking vehicles — because it’s just a different unibody cast based on the same underlying battery architecture and casting technology. In the Fremont factory, we even witnessed how Tesla can switch a component in its casting machine to make different components that it stores in the warehouse section of the factory.

In any case, for the near future, there will still be a marriage ceremony in the factory, but it won’t be a battery skateboard married to the body. For the intermediate step, it will be the marriage of the unibody and the structural battery with the front and rear crumple zones that are also casted whole but separately from the unibody.

So, in the end, Tesla has abandoned the skateboard for its cheaper vehicles, but its replacement, the structural battery pack, not only increases safety and creates more room in the vehicle for other purposes, but has also brought the company closer to the unibody stamping goal we saw laid out in the patent.

So, rather than just eliminate modules and go to cell-to-pack batteries like CATL did, here Tesla went a step further and and invented a cell-to-body solution by making the battery pack part of the structure rather than precious cargo. Considering all we know now, when Elon Musk said that the Model Y made in Giga Berlin would be a whole different vehicle, he wasn’t kidding.