by Peter Diamandis: How do you feed 8 billion people, all of whom want access to higher-quality, more nutritious and lower-cost protein?

Do we raise more cows, pigs, and chicken? Will we be forced to clear-cut more rainforest to raise grains?

Do we raise more cows, pigs, and chicken? Will we be forced to clear-cut more rainforest to raise grains?

Over the next decade, we are reinventing how we feed a hungry planet, transforming what we eat and how we grow it.

We are now witnessing the birth of the most ethical, nutritious, and environmentally sustainable protein production system devised by humankind.

I’m referring to a field known as cellular agriculture or stem-cell based meat production, a field that is poised for rapid demonetization. Over time, producing a cell-based beef burger has fallen 10,000-fold from $1M/kg in 2000 to about $100/kg in 2020.

This cost is expected to fall below $10/kg by 2025, thus creating a mass-market cost-equivalent way of replacing beef at minimal environmental cost and reducing animal slaughter. Similar price reduction is being seen in stem cell-based chicken and fish.

This technology will allow the production of beef, chicken, and fish anywhere, on-demand, and will be more nutritious and environmentally friendly than traditional livestock options.

Companies such as OMeat, JUST, and SCiFi Foods are now scaling production.

At the same time, how we grow our crops is also evolving through the use of “vertical farms” which offer a flexible solution to global agricultural challenges such as volatility due to climate changes, droughts, and floods.

Studies show that vertical farming has multiple advantages: First, it can produce crops that are more nutritious. Second, vertical farms can yield up to four food-production harvests per year, something that is impossible in traditional agriculture. Third, it significantly reduces the transport costs of food because it is produced in close proximity to the point of consumption. Finally, vertical farming is healthier as it reduces the need for pesticides.

This Metatrend is enabled through the convergence of biotechnology, material sciences, sensors, robotics, machine learning, into a field known today as AgTech.

In today’s blog, we’ll take a brief tour of humanity’s access to food and discuss the latest developments and leading companies in vertical farming and cellular agriculture.

Let’s dive in!

A BRIEF HISTORY OF FEEDING THE WORLD

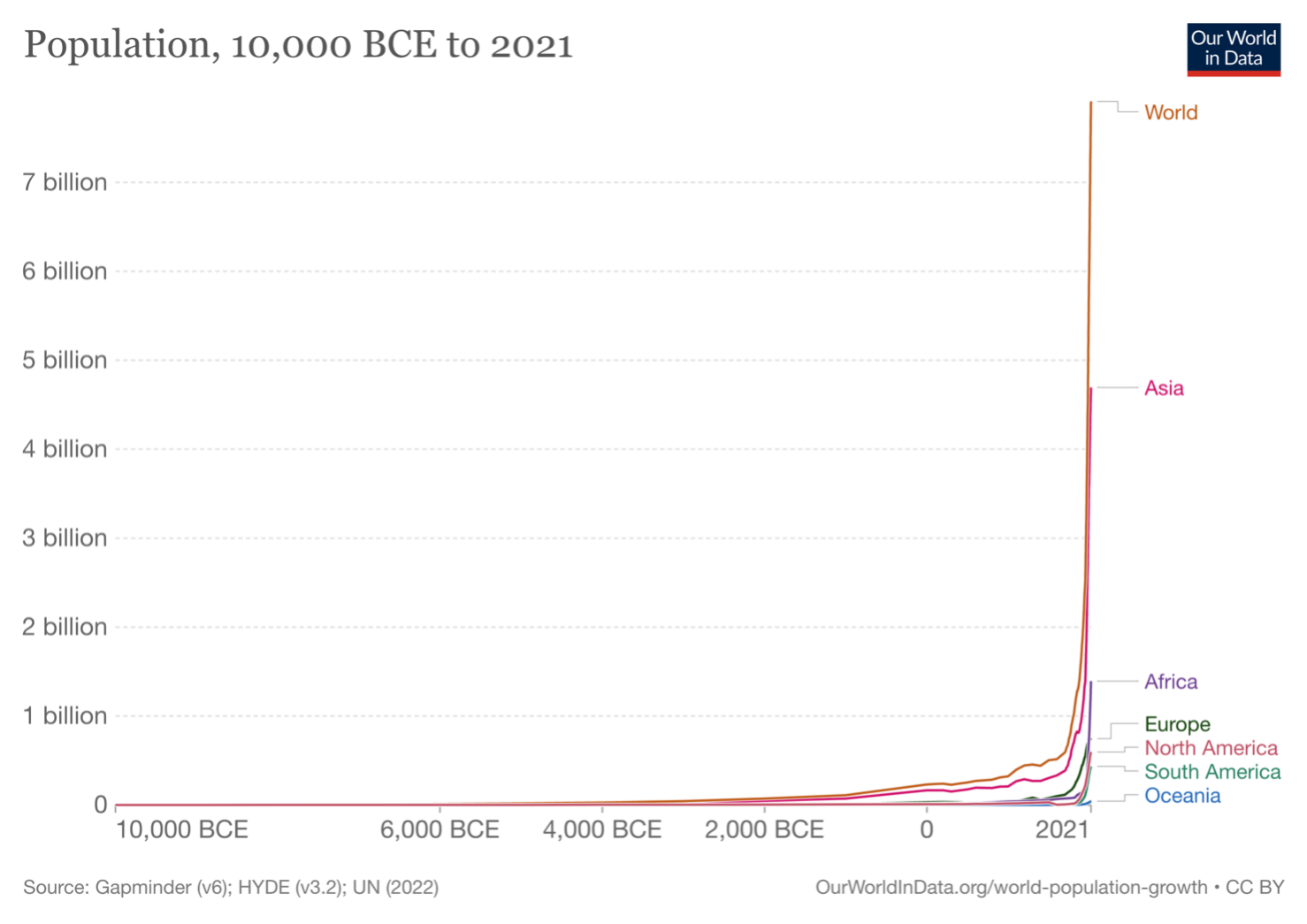

Let’s put food production into perspective and look at the history of humanity’s access to food over time. This is a story that is (obviously) tied closely to population growth.

Prehistoric Era: During the prehistoric era, when the total human population was only 5 to 10 million people, early humans lived as hunter-gatherers, relying on wild plants and animals for sustenance.

Agricultural Revolution: The Agricultural Revolution, which began around 10,000 BCE, marked a significant turning point in human history. For the first time, we started to cultivate crops and raise livestock, providing a reliable source of food and allowing for the growth of settlements and the rise of civilizations. These developments also led to a ballooning population—by the year 1 CE, the world’s population was estimated to be roughly 300 million people.

Middle Ages: That population then increased to around 450 million during the Middle Ages, when access to food was heavily influenced by economic and social systems, including the feudal system in Europe.

Industrial Revolution: The Industrial Revolution, which began in the late 18th century, had a profound impact on humanity’s access to food. New technologies—from the steam engine to the mechanical reaper—revolutionized agriculture and enabled the mass production of food. By 1900, the global population had grown to approximately 1.6 billion people.

Today/Modern Era: Today, in the modern era, access to food has been shaped by globalization, technological advancements, and the growth of the food industry. For most of the world’s population of 8 billion people, food is readily available in most parts of the world due to advanced transportation and distribution systems. Yet despite these advances, it’s estimated that over 800 million people still suffer from chronic hunger.

AGRICULTURE & FOOD BY THE NUMBERS

The total area of Earth is just over 13 billion hectares and about one-third of that, or 4.7 billion hectares, is dedicated to agriculture, according to the UN’s Food and Agriculture Organization (FAO).

At the same time, 26% of the planet’s ice-free land is used for livestock grazing.

In total, agricultural production uses about 70% of the Earth’s fresh water and makes up about a third of greenhouse gas emissions.

So, what exactly are we producing with all this land dedicated to agriculture? Here are some of key stats of the current system:

- The global value of agriculture, forestry, and fishing is currently estimated at $3.6 trillion, more double the value of $1.6 trillion in the year 2000.

- According to the FAO, world production of primary crops was 9.3 billion tons as of 2020, a 52% increase over 2000 production levels.

- Four key crops account for half the global production of primary crops: sugar cane (20%), maize (12%), wheat (8%), and rice (8%).

- Earth is home to over 33 billion chickens around the world—triple the number in 1990. Global chicken meat production is estimated at nearly 103 million tons.

- There are about 5 billion cows in the world and annual beef production is just under 60 million tons.

- The planet’s 1 billion domestic pigs and global pork production in 2022 was roughly 114 million tons.

- Global fish and seafood production has quadrupled over the past 50 years. Much of that increase is due to overfishing: the World Bank estimates that nearly (shockingly!!!) 90% of global marine fish stocks are fully exploited or overfished.

REINVENTING FOOD PRODUCTION

As the number of people on Earth continues to increase, from 8 billion to 9 billion, and as people’s living standards are also going up, they’re demanding higher-quality protein.

For example, the FAO estimates that consumption will grow up to 70% by 2050. And global seafood consumption is expected to increase 23 million tons annually by 2030.

At the same, the conventional systems for producing all this food continue to harm the planet. For instance, producing meat takes up 80% of all agricultural land, and contributes to around a fifth of all human-produced greenhouse gases.

Given these trends, HOW CAN WE POSSIBLY FEED OUR GROWING GLOBAL POPULATION in a healthy and sustainable way?

Do we tell people, “NO, you can’t have access to high-quality protein?” or do we continue to overfish? Or clear-cut more rainforests to raise more feedstock and livestock?

That would be insane.

Or do we use technology to transform “scarcity into abundance” and reinvent how we produce food?

Two of the key technological advancements will make this reinvention possible are vertical farming and cellular agriculture.

VERTICAL FARMING

Vertical farming, whereby food is grown in vertical high-rises (i.e., in skyscrapers and buildings rather than outside in fields), represents a classic case of converging exponential technologies.

Over the past decade, the technology has surged from a handful of early-stage pilots to a full-grown industry.

There are already over 2,000 vertical farms filling plates across the US.

Estimates project the global vertical farm industry could reach over $7 billion by 2025, and up to $20 billion by the end of this decade.

Think about it. The average American meal travels 1,500-2,500 miles to reach your plate (e.g., beef from Argentina, wine from France, and cheese from the American Midwest).

And because up to 50% of a food’s final retail price comes from transportation, storage and handling, these miles (and the associated costs) add up quickly.

Vertical farming addresses this and several other shortcomings of our current food system.

Here are 5 benefits of vertical farming:

(#1) 24/7 growth cycles: Controlled lighting and nutrients in vertical farms allow for year-round food production, 24 hours per day, 7 days per week, regardless of weather conditions or season. This results in higher crop yields, a more consistent supply of fresh produce, and increased food security.

(#2) Fresher food: The longer that foods are out of the soil, the less nutrients they retain, losing on average 45% of their nutrition before being consumed. Produce coming from a vertical farm can make it to you table in under a day. Think “farmer’s market” all the time.

(#3) Reduced water use: Relying on hydroponics and aeroponics, vertical farms enable 90% less water use than traditional agriculture.

(#4) Reduced carbon footprint: Because vertical farms eliminate the need for transportation of fresh produce and are located closer to urban areas, they can reduce their carbon footprint by up to 90% compared to traditional farming methods.

(#5) Reduced Pesticides: Vertical farms grow crops in a controlled environment, which eliminates the need for pesticides and herbicides. This results in a higher-quality product that has a longer shelf life compared to traditional farming methods.

With these benefits in mind, let’s look at 3 of the top vertical farming companies leading the industry forward…

TOP 3 LEADING VERTICAL FARMING COMPANIES

Plenty: Founded in 2014, Plenty has about 200 patents to its name and grows its crops in 30-foot vertical towers in a modular fashion.

When compared to traditional farming, Plenty’s setup allows the company to produce yields of up to 350-times more per acre, while using a fraction of water and just 1% of the land required by conventional farms.

In 2022, as part of a $400 million Series E funding round, Walmart bought an equity stake in the company. The move marked the first time a major US retailer put a significant investment into vertical farming. In addition to financing, Plenty also signed a commercial agreement with Walmart to “lead a new category of fresh products and bring Plenty farms closer to Walmart customers to offer pesticide-free, sustainable produce year round.”

Plenty also recently announced that it is building what might be the world’s largest indoor vertical farming campus on 120 acres in Virginia. The $300 million facility will grow various crops, including leafy greens and tomatoes, starting with a Driscoll’s strawberry farm later this year. In total, the vertical farm will produce up to 20 million pounds of produce per year and create 300 new jobs.

Crop One: Crop One has continuously produced fresh, local, and safe leafy greens 365 days a year since 2015. It’s also responsible for two of the largest vertical farms in the world: ECO1 in Dubai and a new facility going up in Pennsylvania.

ECO1 is a 330,000-square-foot vertical farm located in one of the hottest, driest places you can find: the United Arab Emirates.

The facility functions like other vertical farms, using LED light and a cocktail of nutrients to grow plants without soil or light. But what differentiates ECO1 from most of other vertical farms is its scale: the Dubai-based facility can produce over 2 million pounds of leafy greens annually, including lettuces, arugula, mixed salad greens, and spinach.

Crop One is also building a new 316,000-square-foot vertical farm in Pennsylvania. The facility will produce 7 tons of produce per day once fully operational in 2024, focusing on romaine lettuce and spring mix greens.

Upward Farms: Upward Farms was founded in 2013 and currently sells microgreens in 21 Whole Foods Markets and other stores throughout the New York metropolitan area.

Those greens are sourced from the Upward Farms’ 2 existing farms in New York City, and the company just announced that it is building an even larger vertical farm in Pennsylvania.

The new facility 250,283-square-foot indoor farm will be one of the largest vertical farms in the world and is designed to reduce water and land use by 95% while eliminating 1.7 million food transportation miles per year. It will produce microgreens and leafy greens, as well as hybrid striped bass.

As Upward Farms CEO Jason Green puts it, “We’ll be able to reach nearly 100 million Americans, within a single day of distribution versus the week it can take to receive products from the West Coast.”

The new Pennsylvania facility is slated to be operational by the end of this year.

We’re also seeing robots enter the picture. Currently up to 80% of a vertical farm’s cost is human labor, but the Silicon Valley–based Iron Ox has designed a 1,000-pound robot that can tote around 800-pound growing containers.

In short, not only is farming getting taller, it’s getting stronger. And smarter. And most importantly: far more efficient.

CELLULAR AGRICULTURE: THE PROTEIN REVOLUTION

Rather than raising the entire cow, chicken, or tuna just to get access to the meat, why not just grow the meat part of the animal?

Imagine if we could start with a single muscle stem cell and grow just the muscle tissue, in other words the steak, without needing the rest of the cow? Imagine returning millions, perhaps billions, of acres of grazing land back to the wilderness?

This is the promise of lab-grown meats (or “cellular agriculture”).

Cellular agriculture works by painlessly taking cells from a living animal, and then feeding those cells a mixture of nutrients and naturally occurring growth factors (e.g., amino acids, vitamins) so that they multiply billions-fold.

Here are 3 benefits of cellular agriculture compared to conventional methods:

(#1) Better for the environment: Cultured meat uses 99% less land, 82% to 96% less water, and produces 78% to 96% less greenhouse gases. Additionally, with cellular agriculture, energy use drops between 7% and 45% depending on the meat involved (e.g., traditional chicken ranching is much more energy intensive than traditional beef ranching).

(#2) Healthier food: Cultured meat is also a healthier solution. For example, since we’re growing steak from stem cells, we can increase helpful proteins, reduce saturated fat, and even add vitamins. Lab-grown meat can also be engineered (using technologies like CRISPR) to be packed with nutrients and be the healthiest, most delicious protein possible. The meat requires no antibiotics and given the danger of diseases like mad cow, is actually safer for humans. By turning to cultured meat, we’re lowering the global disease burden and, since 70% of emerging diseases come from livestock.

(#3) Increased efficiency and lower costs: In traditional farming, many factors can impact the growth and production of crops, including weather patterns, disease outbreaks, and pest infestations. With cellular agriculture, these factors are greatly reduced, as crops are grown in controlled environments, such as greenhouses or bioreactors. This leads to consistent, reliable yields, reduced food waste, and when combined with continuing technological advances, ultimately food that is cheaper.

We’re watching this technology develop in real time.

As of 2022, over $4 billion had been invested in the cellular agriculture industry, and McKinsey estimates that the cell-based meat market could reach $25 billion by 2030.

Several startups across the globe are already working to bring artificial meats to the food industry.

To help with that mission and further spur innovation in the field, back in 2018 with backing from the Abu Dhabi government and Tony Robbins the XPRIZE launched a $15 million multi-year competition called “Feed the Next Billion” to incentivize teams to produce chicken breast or fish fillet alternatives that replicate or outperform conventional chicken and fish in: access, environmental sustainability, animal welfare, nutrition, as well as taste and texture.

Now, let’s look at some of the top companies creating the future of food, organized by the type of meat they’re producing…

LEADING CELLULAR AGRICULTURE COMPANIES

Companies Producing Chicken

GOOD Meat: In 2020, GOOD Meat, the cultivated meat division of Eat Just (a company for which I am an advisor), became the first company in the world to start selling lab-grown meat, with its cultured chicken hitting the commercial markets in Singapore.

In addition, last year, they launched a cultivated chicken satay at local hawker stalls and a neighborhood butcher shop (both world firsts), and they also announced a new partnership to develop the world’s largest bioreactors (250,000 liters) for animal cell culturing, with the capacity to produce up to 30 million pounds of meat each year.

UPSIDE Foods (formerly Memphis Meats): In November 2022, UPSIDE Foods became the first company to receive a “No Questions Letter” from the FDA. This approval is a key milestone (two more are needed) on the road to allowing the company’s sale of lab-grown chicken to consumers.

Fresh off a $400 million series C funding round in 2022, UPSIDE Foods is focused on creating its commercial-scale facility, perfecting its supply chain, and partnering with big names in the food and retail industry, including Whole Foods (which is an investor) and the chef Dominique Crenn, who will help bring the company’s product to restaurants.

Believer Meats (formerly Future Meats): Believer Meats made headlines in 2021 when it announced that it had brought the cost of a cultured chicken breast down to $7.50. Then 10 months later, it said it can make a 110-gram chicken breast for just $1.70.

The company’s process involves animal cells fermenting in stainless steel vats as waste products are continuously removed, resulting in yields that are 10x higher than the industry standard. In December 2022, the company broke ground on what will be one of the largest cultivated meat plants in the world, with the capacity to produce 11,000 tons of cultivated meat.

Companies Producing Beef

SCiFi Foods: In 2022, SCiFi Foods made the game-changing announcement that it had achieved price parity with beef. Using proprietary tech that combines its own high-throughput cell line engineering and CRISPR technology, the company was able to reduce the cost of cultivated meat by 1,000 times. The result is a “blended burger” that’s part plant-based and part cultivated meat at a cost of less than $10 per burger.

The company estimates that with large-scale production, cultivated beef prices will fall even further, eventually down to $1 per burger.

OMeat: Los Angeles-based startup Omeat (a company backed by my venture fund BOLD) is using its tissue engineering and biomedical expertise to develop a scalable approach to cultured meat.

Founded by renowned tissue engineer and former MIT and Harvard professor Dr. Ali Khademhosseini, the company is focused on growing real meat that is just as delicious as conventional meat but without the environmental consequences of the current agricultural system. Dr. Khademhosseini will also be sharing his insights on how we can feed the world through cellular agriculture at next month’s Abundance360 Summit.

Aleph Farms: Cultivated meat startup Aleph Farms has achieved multiple firsts in the industry, including: 1st cultivated beef steak in 2018, 1st cultivated meat grown in space in 2019, and 1st cultivated ribeye steak in 2021.

The company’s process, which combines 3D bioprinting and stem cell science, allows it reduce land and water usage by up to 95% and greenhouse gas emissions by up to 90%. Aleph Farms just moved into a new 65,000-square-foot facility and is on track to launch their beef product in both Israel and Singapore this year.

Companies Producing Pork

Novel Farms: Berkeley-based foodtech startup Novel Farms has successfully created the world’s first slaughter-free pork loin that displays the texture and marbling of a real muscle cut.

Unlike competitors in the cultivated meat industry that add biomaterials such as alginate and cellulose to make the meat structure, Novel Farms’ tech is able to bypass that step, reducing the scaffolding production costs by 99%. The company expects to get its pork loin to customers in 2025, with commercial mass production in 2027.

Meatable: Dutch cultivated meat company Meatable unveiled its synthetic sausages in 2022. Rather than using fetal bovine serum (FBS), the company uses opti-ox technology, which is based on a single cell from the umbilical cord of an animal and allows it to create cultivated meat without any harm to the animal.

Meatable plans to bring its pork product to the Singapore market in 2024, with supermarket-ready products (e.g., pork dumplings) by 2025.

Companies Producing Fish

Wildtype: One of the leaders in the alt seafood market is Wildtype, which recently raised $100 million in a Series B round for its “sushi-grade” cultured salmon. The company grows the cells of Pacific salmon in steel tanks, and then puts them in “scaffolds,” structures made of plant-based ingredients to guide the cells to shape each cut of fish.

Wildtype’s pilot plant is capable of producing up to 200,000 pounds of cultivated seafood annually, and the company expects to launch its salmon product in US restaurants in 2023.

Bluu Seafood: German company Bluu Seafood unveiled its first 2 products in 2022: fish sticks and fish balls, which are made from cultivated fish cells and then enriched with plant proteins. The company is also working on creating Atlantic Salmon, rainbow trout, and carp.

Bluu Seafood plans to start its pilot production this year, entering the first phase of the product’s commercialization.

FINAL THOUGHTS

Add this all together and we see a very different future of food.

Slaughterhouses may become ghost stories we tell our grandchildren. We may have a chance of re-populating our oceans and giving back billions of acres of grazing land to the rain forests.

And a planet that is already strained under the weight of 8 billion souls will have a fighting chance when our numbers top 9 billion.

(This blog is written by Peter H. Diamandis, MD and Cheo Rose-Washington)